When it comes to business and the economy, there’s constant buzz about Apple, Amazon, Google, and Facebook. There’s also been lots of attention lately on middle America and the loss of manufacturing jobs. At times these topics seem at odds – the new high-tech guard disrupting the old, jobs shifting from blue to white collar, outsourcing overseas versus keeping things at home, and the list goes on.

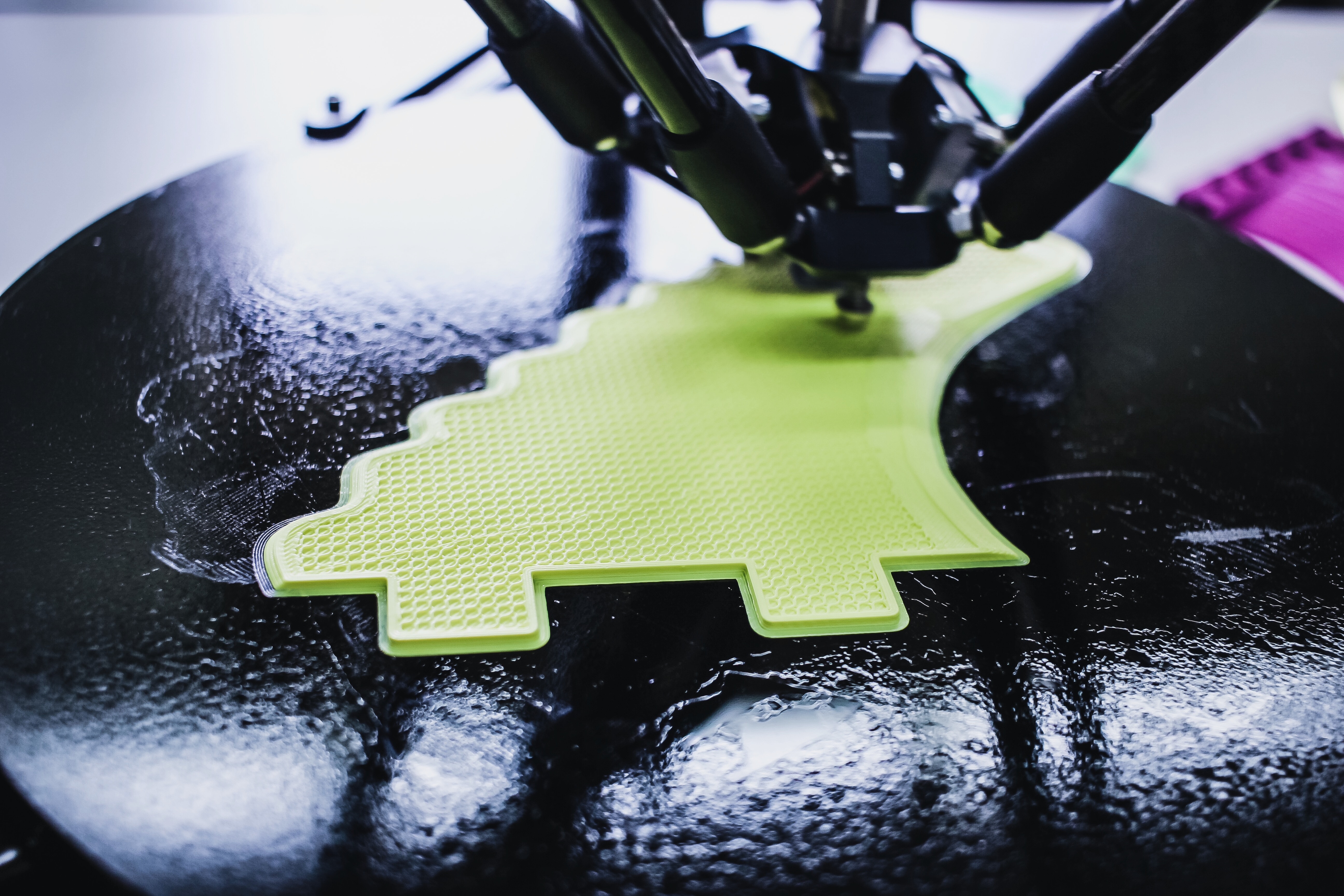

These hot debates have been obscuring a major phenomenon in the Rust Belt. Manufacturing, the making of physical things, is roaring into the 21st century with its own approach to digitization and platforms. 3D printing promises to do for industry what the internet has done to the information world. No longer relegated to trinkets or prototyping, 3D printing is now going into full-scale mass production. Just take a look at what some of the leaders are doing like 3D Systems, Stratasys, Arcam, and HP.

That’s my takeaway from a new book, The Pan-Industrial Revolution: How New Manufacturing Titans Will Transform the World. It’s written by Richard D’Aveni, a professor of strategy at Dartmouth’s Tuck School of Business.

The book explains why 3D printing, or more generally additive manufacturing, will do more than just alter the factory floor. It also promises to reshape competition. 3D printers are amazingly flexible: they can make a product one week, and then a very different product the next week, with minimal changeover costs. The same factory can therefore make parts and products for a wide range of industries.

That’s a game-changer: companies will finally achieve operational synergies across multiple divisions. After all, if you have a factory devoted to only one industry, and demand drops, you’re stuck. But if you’ve diversified into multiple divisions, you can switch over the factory’s capacity to the industry with stronger sales, and keep the factory running at a high level.

D’Aveni predicts the emergence of many such “pan-industrial” companies, gradually squeezing out focused manufacturers. They’ll have an edge not just in factory utilization, but also in reducing supply chain, distribution, and even product development costs. Just imaging a factory, not with robotics and assembly lines, but with rows of 3D printers cranking out whatever you want when you want it.

Where do traditional small manufacturers fit into this? D’Aveni offers a mixed prognosis. The bad news is that the only way to compete directly with a pan-industrial is to get big yourself, so you can achieve the economies of scale and scope that come from additive manufacturing. Also, with 3D printing, companies can produce complex, integrated designs with fewer parts to be assembled. So, a lot of small, focused suppliers may be challenged to stay afloat since everything needed for whatever you’re manufacturing comes directly out of the printer.

The good news is that the bigger players will likely invite outside companies to join their software platforms. Like the software giants, these pan-industrials will create digital marketplaces turbocharged by network effects. By joining a pan-industrial platform, a small manufacturing company will get access to customers and all sorts of ancillary services, similar to what they get from Apple or Amazon’s platforms.

This is all about the future, as there aren’t any full-fledged pan-industrials yet. D’Aveni points to Jabil, Siemens, and some other industrial leaders as candidates. The software giants like Google, Adobe, Autodesk, Apple, and Amazon might even use their digital prowess to get in on the action.

These “pan-industrials” will likely emerge in the next few years. In the meantime, D’Aveni urges companies big and small to do these three things:

- Raise the alert and start learning about the current state of additive manufacturing: is it now cost-competitive with your current production techniques?

- Try out some additive equipment. You’ll understand not just the production advantages but also how you can digitize areas you never could before, including product innovation.

- Expand your horizon beyond your immediate industry. Additive is going to dissolve industry boundaries, so a competitor (or friendly platform operator) could emerge out of nowhere.

If D’Aveni is right, ten years from now, we may have the same excitement and fear with pan-industrials that we now have with the software giants. And even if he’s only half right, companies need to start preparing for the additive revolution — or get left behind.

Soren Kaplan is the bestselling and award-winning author of Leapfrogging and The Invisible Advantage, an affiliated professor at USC’s Center for Effective Organizations, a former corporate executive, and a co-founder of Praxie. He has been recognized by the Thinkers50 as one of the world’s top keynote speakers and thought leaders in business strategy and innovation.