The U.S. economy is humming along through a period of expansion with a noteworthy contribution from the manufacturing sector. The manufacturing industry of the United States has been contributing to more than 10 percent of the GDP, representing over 8 percent of the employed population in the U.S. The contribution is so strong that manufacturers are highly optimistic about the jobs generation in the months to come.

However, the rising number of open jobs and filling them has become a huge challenge for the industry in recent years. According to a skills gap study undertaken by Deloitte and The Manufacturing Institute in 2018, the number of unfilled jobs is expected to rise from 488,000 today to up to 2.4 million between 2018 and 2028.

As per this study, 4.6 million manufacturing jobs will be open for filling from 2018 to 2028. Of these, only 2.2 million jobs are expected to be filled. That means 2.4 million (or 53 out of 100) open jobs are likely to remain unfilled due to skills shortage in the manufacturing industry. Such a workforce crisis can pose a risk to $454 billion of manufacturing GDP in 2028 alone or over $2.5 trillion over the next decade.

While manufacturers in the U.S. are experiencing high levels of growth, the industry is unable to keep up with the resulting rebound in the growth of jobs. About 2.7 million jobs will be vacated in the industry from retirements and 1.7 million new jobs will emerge due to natural growth by 2028. This number of open jobs will be greater than ever and not only challenge the businesses but may threaten the vitality of the sector and the economy as a whole.

A wide variety of factors contribute to creating this workforce shortage and it is widening. According to the study, many companies would find it more difficult to fill skilled positions in the coming years. Presently, many of such jobs take longer to fill, impacting the company’s ability to complete orders, fulfill customer needs and expand production.

An important reason for the current talent shortage is the shift of skills occurring due to the introduction of advanced technology and automation. Half of the manufacturers have already adopted the latest technologies like machine learning, robots, artificial intelligence, etc. In such an age of the Internet of Things, types of skills employees should possess evolve rapidly, making it difficult for the workforce to keep up. Another reason is the retirement of baby boomers which results in a loss of experienced workers. The third reason is the negative perception of students and their parents about the manufacturing industry.

Manufacturing companies are trying to fill the skills gap through many methods. Short term solutions include attracting and retaining workers by raising wages, allowing non-production jobs to be done from remote locations and introducing broader HR policies. Making hiring requirements flexible like looking for potential rather than work experience can really help fill the skill shortage. Long term solutions require companies to focus on ways to continue using the knowledge of retired workers, keeping them accessible to queries and hiring them for short-term assignments after they retire. Another solution is to explore newer methods of talent sourcing like the use of gig platforms. Companies can also consider establishing collaborations with universities, governments, and other public institutions. The creation of digital training platforms to create and retain talent can also help. Automation, though initially believed to threaten human jobs, is now being used to supplement low-skilled jobs that manufacturers are not able to fill. They focus on skilled workers on human jobs or higher-skilled tasks.

To address the manufacturing skills gap at a broader level, companies should not only invest in technology for training but also in apprenticeship programs to teach the skills required in digitalized manufacturing. Such programs are already introduced and employ high school students while they earn their degree. This type of programs not only changes the perception of the sector but also ensures workers enter the workforce with all the necessary skills. There are other solutions including high school internships and two-year programs along with flexibility in education. These are some of the methods that can go a long way towards solving the skills gap in manufacturing.

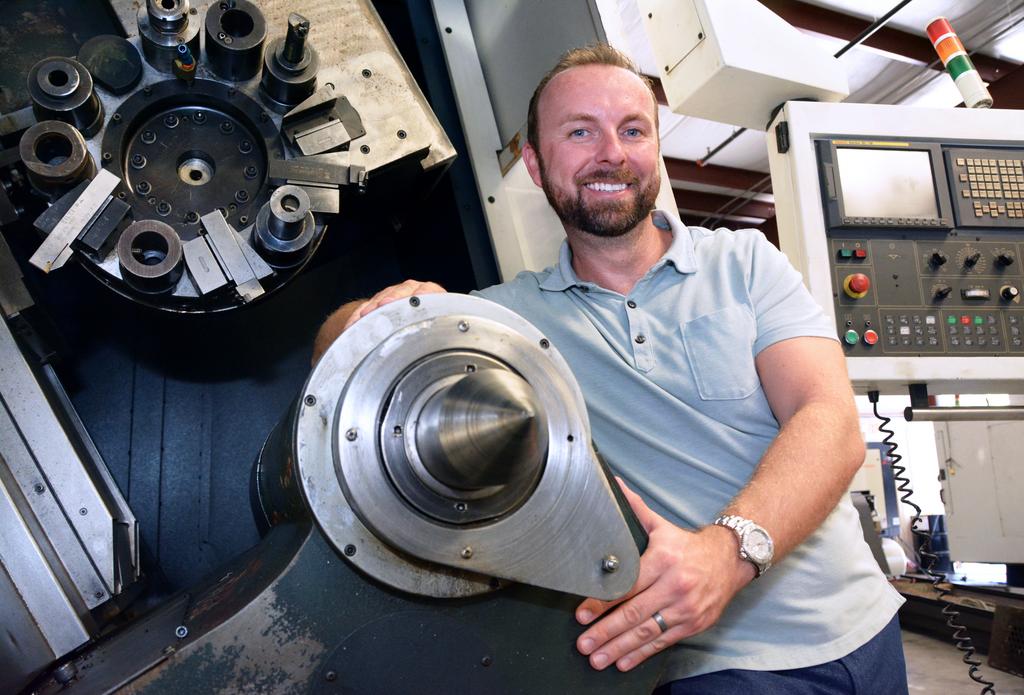

A wonderful example of such an effort is the announcement made by CNC Machines for an annual scholarship for students pursuing a certificate, degree or bachelor’s degree in manufacturing, engineering, and other related fields. It is a Florida based company that provides a marketplace for buying and selling used CNC machines. The CNC Machines Manufacturing Scholarship program was introduced in 2018. The purpose of this scholarship is to highlight the need to invest in the rising skills gap in manufacturing in the United States. The mission is to set an example for manufacturing and engineering companies to start introducing their own programs rather than relying on trade associations alone. A scholarship of $2500 is awarded each year to a student studying in a manufacturing-related course. Applicants submit an essay of 1000-1300 words about why they chose to pursue a career in the manufacturing sector, what they think can be done to attract younger generations into the field and their own goals, skills, and future plans.

This scholarship program introduced by CNC Machines is a great topic that shows the value of investing back into the U.S. economy, especially for the growth of the manufacturing industry. This program is not the only effort made by this company to fill the skills gap. It has also awarded scholarships to veterans looking for education and training to become skilled machinists. This company is also a member of SME – a non-profit organization of educators, professionals, and students committed to supporting and promoting the manufacturing industry.