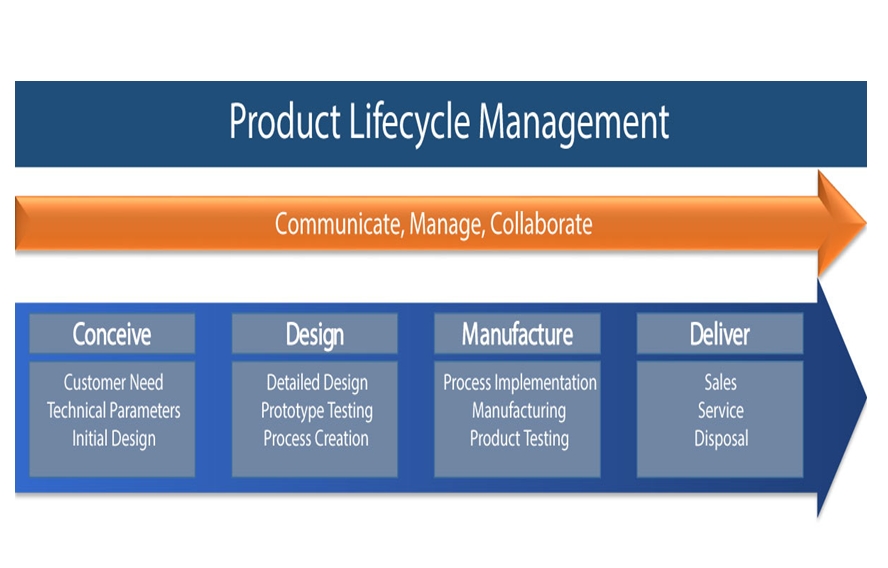

In the present scenario, the PLM has become more popular in the industry. It stands for Product Lifecycle Management. It is the corporate management process and essential data associates to services or products throughout their lifecycles. In simple and easy terms the PLM compiles different application which plays a vital role in the real product creation like the PDM, CAD, CAM, and CAE and manufacturing supply chain and execution management. For instance, in the medical device industry, the PLM provides very important compliance. In the below mention section you can get more details about the PLM

Need and Benefits of PLM

For companies as well as manufacturers nowadays need to source, design, distribute and produce products across the world. So it is essential to have the single source to deal with all the data and processes. Having the PLM system is the best method to achieve this. It has become essential as the single source for managing all product aspects from primary development to product retirement. Below mentioned are the benefits of having the Lean IT PLM system:

- Short time to market : The product development can be finished faster. The experienced and skilled design team will work so fast and speed up the transfer of design data to manufacturing. In this situation the moving fast can be important, quicker product development and a short time to market are so essential to stay competitive.

- Decrease compliance risks : The PLM has the ability to manage a single account of truth for entire product data. This serves to ease fulfillment risks. The cost prevention is the main benefit of product legal fees, recalls, lost productivity and many others.

- Reduce cost : By using the PLM it gives more chances to decrease material as well as production costs. This reduces come from the two sources such as the prototyping and scrap.

- Increase productivity : This is another benefit of using the PLM software. It aids to increase the productivity. Another advantage is that it will work on product development.

- Excellent data analysis : The PLM is the simple and easy process which involves product organizing or service tools, cycle, workflow and information all through a variety of departments of a company. The process permits for an improved flow and communication between employees, customers, processes and IT tools. The complete documentation is particularly significant when it comes to medical device management. It is because they have a straight association with human beings and the system in order to protect them. The history file of design is recorded from the planning stages via many manufacturing changes of the product.

- Integrated business functions : These days most of the business owners have many numbers of departments with each and every company. From the supplies and manufacture to compliance and financial divisions. It has a primary purpose to make the company well-organized. When you are necessary to fulfill with FDA rules & regulations and other essential issues, the PLM allows each and every one of your departments to labor on the racing bike without missing any steps. In addition to incorporating a variety of departments, you can also computerize processes, go into different products, and keep a close-up watch on costs.

- Transparency : The transparency is an essential element of a company’s success. It is because it is helpful in the policy disclosing and decision-making process. It is a line of a message between the owners, customers, managers, and other employees. This open conversation affords a company the opportunity to study its data to observe what works and what does not work. The product life cycle management can also suggest a video recording of several items credits, purchased, and another significant sequence of which a business has to remain track.

- Available in one place : Basically, the PLM knows how the essential device compliance to the company. The device master records in it can capture each and every part, drawing, instruction, process, document, and cost related to the medical devices. This aid and provides your business with a reliable and apparent image that is both centrally situated and easily reached all in a single place.

- Enhance product quality : The PLM generally make it simple and easy to control and manage all the facts that effect in general product quality. By using the PLM, the manufacturers are capable to execute all the procedures and processes essential to sustain the product quality as well as the customer satisfaction. This is particularly essential for the instances when teams are extending across dissimilar places, to make sure that quality does not cooperate.